Categories

- Wire & Cable

- Multi-conductor & Signal Cable

- Battery Cable Assemblies

- Terminals and Connectors

- Electrical Parts

- Electrical Tools

- ID Products

- Wire Management

- Tape & Sealant

- Mounting Panels & Panel Blanks

Need Help?

Click HereGet a Business Account

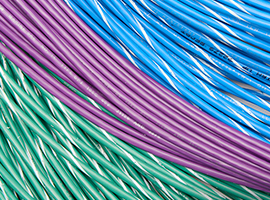

Apply HereStriped Marine Wire

![]()

![]()

![]()

![]()

![]()

![]()

![]()

What is Striped Marine Wire?

Striped marine wire is primary wire that has been color-coded to make identification easier. How? A stripe, or two, of varying colors is added to the insulation of a wire. You may ask yourself, How can this be useful? Well, the answer becomes clear when dealing with the multitude of wires that can be found in various environments and vehicles, such as a marine vessel.

"With over 100 possible combinations, you're sure to find the striped wire you need."

Think about it: once you get twenty, fifty, eighty, or more wires in an electrical system, how do you know which wire controls which piece of equipment? In addition, consider having a bundle of wires that extend through a hull. Their point of origin will not be visible. If all the wires look the same, determining which wire attaches to which piece of equipment would be a daunting task.

The idea for striped marine wire came as a solution to this very issue. A simple colored stripe on the insulation of a wire can change its designated purpose. What kind of stripe options does Pacer carry? When offering striped marine wire, the most important aspect is choice. Pacer has gone out of the way to provide just that. Whether you're looking for a blue wire with a red stripe or a yellow wire with a black stripe, you'll find it here. With over 100 possible combinations, you're sure to find the striped wire you need.

All Pacer wire is built from type III class K tinned copper and carries proprietary insulation designed for flexibility, durability, and longevity. When we manufacture wire, we make it to handle the toughest marine conditions. Our wire is trusted by some of the world's largest boat builders and is used in a wide range of industries. Take a look at why you should use Pacer striped marine wire.

Why use striped marine wire?

Striped marine wire makes the process of identifying a wire’s designated purpose much easier. This, in turn, makes maintenance, repair, and replacement of wires and parts much easier as well. Say you need to replace a wire to one of your bilge blowers. Now imagine looking at the wiring harness and seeing twenty or thirty wires of similar-colored insulation. It would take forever to find the correct one. If you had used striped marine wire, you would know to look for the brown wire with a yellow stripe. So, you see, the reason you want to use striped marine wire is so that your electrical system is easy to navigate, maintain, and repair.

![]()

Durability

![]()

Flexibility

![]()

Longevity

Where is striped marine wire implemented?

Striped marine wire is available in many combinations.

Striped marine wire is implemented in just about any marine environment where there are a multitude of wires to be distinguished from one another. This is one of the many reasons that some of the largest boat builders in the world turn to Pacer for their striped wire. Beyond that, it is utilized by everyday boaters as well. Oftentimes, when an everyday boater finds cracked wire insulation, damaged wires, or faded wires, they turn to Pacer for their replacement wire. With the proper tools, terminals and connectors, and heat shrink, you can quickly and easily install our striped marine wire.

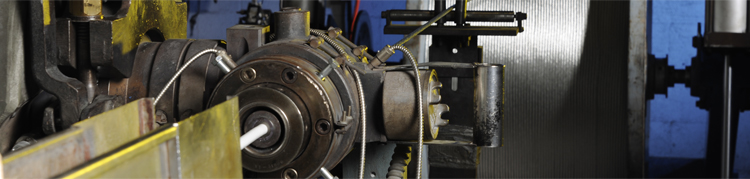

How is it manufactured?

All Pacer striped marine wire is manufactured in-house in Sarasota, FL, USA, from annealed, finely stranded Type III Class K tinned copper. This type of material isn’t chosen by happenstance. Pacer Engineers have gone above and beyond to use the best materials in all Pacer products. Engineered to be highly conductive and corrosion resistant, this type of wire is well-suited for many harsh environments. This, coupled with the fact that it is finely stranded, leads to increased flexibility and durability. The tinning process further reduces the chances of corrosion setting in. Once the tinned copper is ready, it is jacketed with proprietary insulation designed with longevity in mind. One thing about wire or cable that is going to be used in marine applications is that it needs to be flexible. That is exactly what this wire is built for. The insulation and conductors are so flexible that you can tie them into a knot and then undo that knot with no loss to the integrity of the circuit. The final step in the manufacturing process is the addition of one or more colored stripes. These stripes are painted on using a high-quality material designed to last in the harshest marine conditions.

What types of resistances does our striped marine wire offer?

To be as durable as possible, Pacer striped marine wire is resistant to oil, acid, alkali, gasoline, abrasion, moisture, and flame. In a marine environment, there is a multitude of hazards that your wire will be subjected to. Using a wire that doesn’t carry any form of resistance, or not enough resistance, leaves your electrical system vulnerable. Being resistant to not one or two, but a wide range of environmental hazards gives your wire, and in turn, your electrical system, the durability and longevity it needs to survive long-term in a harsh environment.

![]()

Moisture ![]()

Acid ![]()

Abrasion ![]()

Alkali ![]()

Oil ![]()

Gasoline ![]()

Flame

What compliances does Pacer Wire meet or exceed?

All Pacer striped marine wire meets or exceeds a host of compliances such as UL, ABYC, & USCG. The entire point of having compliances and standards in place is to make sure that products perform at a certain level. Some manufacturers merely build to meet those standards, whereas Pacer builds to surpass them when possible. Below you will find a list of the compliances our striped marine wire meets or exceeds. Simply click on any of the links to be taken to the corresponding standard.

16 AWG - 8 AWG

22 AWG - 18 AWG

What industries use our wire?

Industries such as the marine industry, the RV industry, the automotive industry, the power management industry, the database industry, and many others utilize Pacer’s striped marine wire daily. This shows not only how useful and durable this wire is, but how reliable it is as well. Many industries will not waste time replacing wires when they can use a long-term option. Choosing the highest quality options available will lead to the best results imaginable. In this way, Pacer is providing more than just striped marine wire; we’re offering solutions.

![]()

Marine

![]()

Automotive

![]()

RV's

![]()

Communication

![]()

Golf Cart

![]()

Audio

![]()

Solar

![]()

Batteries

![]()

Database

![]()

Equipment

What are some advantages of using our wire?

The advantages of using Pacer striped marine wire include easy identification, flexibility, durability, and longevity. You will be hard pressed to find another marine wire that carries the same resistances and compliances while offering the same level of conductivity and flexibility. Test it for yourself and see that many other manufacturers create a wire that is stiff compared to Pacer Wire. Every aspect of this wire has been designed, tested, refined, and redesigned to give the highest quality striped marine wire available. The entire point is to offer the highest-quality solution available, and with nearly forty years in the industry, we do just that.

What color combinations are available?

Currently, we offer over 100 possible color stripe combinations depending on the wire gauge selected. Click here to be taken to our catalog and see the available combinations.

*This page was updated on 1/30/2025*