Categories

- Wire & Cable

- Multi-conductor & Signal Cable

- Battery Cable Assemblies

- Terminals and Connectors

- Electrical Parts

- Electrical Tools

- ID Products

- Wire Management

- Tape & Sealant

- Mounting Panels & Panel Blanks

Need Help?

Click HereGet a Business Account

Apply HerePrimary Marine Wire

![]()

![]()

![]()

![]()

![]()

![]()

![]()

What is primary marine wire?

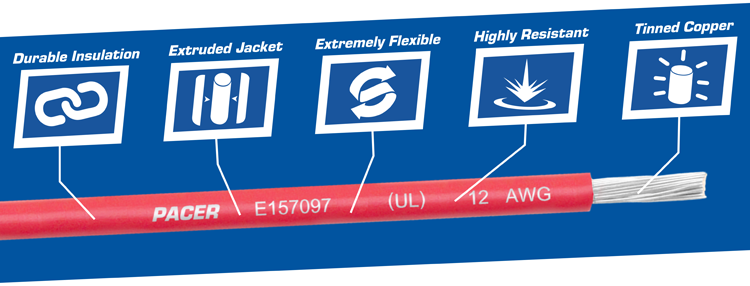

Primary marine wire, commonly called primary wire or boat wire, is electrical wire designed for use in the toughest marine conditions. This means it is built from corrosion-resistant materials, has a strong insulating jacket, follows stringent guidelines such as UL (Underwriters Laboratory), and follows a color code standard.

"It is built from corrosion-resistant materials, has a strong insulating jacket, follows stringent guidelines such as UL, and follows a color code standard."

Each type of electrical wire (marine wire, zip cord, speaker wire, etc.) is designed, manufactured, and implemented with a specific purpose in mind. Using an incorrect type of wire for a given application will not provide the desired results. It is important to only use electrical wires for their approved tasks. Pacer's Primary Marine Wire is the only wire designed, built, and suitable to handle the toughest marine conditions without compromising its flexibility or durability.

The best choice is to use the electrical wire most suited for the application; this is especially true for marine applications. This is because the marine environment is subject to elemental exposure that is not found in other environmental conditions. For example, to resist moisture or corrosion, you need a wire that has been tinned. Without the tinning process, the conductors are subject to the effects of corrosion, resulting in damage to, or failure of, the electrical system. This is why it is important only to use marine-rated wire and cable in your boat. If you want to get the best results possible, you should only use the proper materials that are designed for the environment at hand, which in the case of a marine environment, is marine primary wire.

How is it manufactured?

Pacer Primary Marine Wire is manufactured in-house in Sarasota, FL, USA, from Type III Class K copper. This type of copper is chosen for its high conductivity and durability, which are higher than other commonly used types of conductors. When manufacturing our primary marine wire, we only use fully annealed, finely stranded wire. Using this type of stranded wire provides unbeatable flexibility, which makes it ideal for routing and handling the constant vibration of a marine environment. Now you may think flexibility is not very important since once the wire is installed it doesn’t go anywhere, but there are two problems with that idea.

First, when routing the wires initially, you will need to bend and angle the wires, most likely through tight spaces. Using a primary wire that offers high flexibility can prevent a host of issues, initially and down the road. Secondly, a marine vessel is under constant vibration. That means every second you’re operating your boat your wires are under stress. A marine wire that is extremely flexible is likely to handle that vibration much better than a less flexible wire. In the end, it boils down to how rugged you want your boat to be and how often you want to deal with maintaining or changing out your wires. The next step in our manufacturing process is tinning. We tin all our wire and cable varieties for several reasons.

![]()

Copper ![]()

Tinned ![]()

Stranded

Tinned copper offers an added layer of corrosion resistance, making Pacer’s Primary Marine Wire even more durable in a marine environment. Additionally, tinning copper does not significantly decrease conductivity when compared to bare copper. So, tinning the copper maintains its conductivity while making it more resistant, which in turn makes it ideal for use in the marine environment.

Are tinned copper conductors that important?

Tinned copper conductors are crucial for an electrical system in a marine environment. Anytime you are dealing with marine conditions, you are exposing your wires and cables to moisture that they wouldn’t normally handle. Bare copper is somewhat resistant to corrosion, but that resistance is removed when that bare copper is subjected to continual moisture exposure. This is where tinning the copper comes in. By tinning the bare copper, we extend the life of the primary wire by heavily reducing the chances of corrosion. If somehow the corrosion does find its way to your wire, it will spread much slower. The bottom line is that if your wire is going to be used in a marine environment, it needs to be tinned.

Where is primary marine wire implemented?

Primary marine wire is ideal for demanding applications.

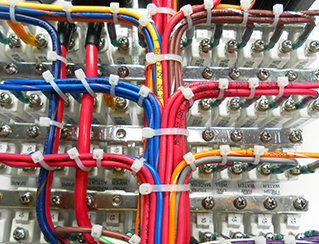

Pacer primary wire is implemented in a range of applications but can most commonly be found in the internal wiring systems on marine vessels. Oftentimes when a boater finds that they have faded wire, cracked wire insulation, burnt wire, or damaged wire, they turn to us for our high-quality solutions. With the proper tools, terminals and connectors, and heat shrink, you can quickly and easily create long-lasting electrical connections. People commonly use our primary marine wire and our marine battery cable together.

How do you know which color insulation to choose?

The point of coloring the insulation is so that its intended use is made obvious to anyone working on your boat. This makes the process of maintaining, repairing, or replacing easier by visually identifying the wire. Let’s say you need to replace the wire running to the water temperature gauge. Then, if your electrical system was wired correctly, all you need to do is find the tan wire and replace it. Below you will find a simple chart showing the most common color codes that are used in boat wiring. This methodology saves on time and repair costs and ensures anyone can work on your system.

| Color | Item | Application | Available Gauges |

|---|---|---|---|

| Black Primary Marine Wire | DC Negative Conductor | Return, Negative Mains | 22AWG - 8AWG |

| Brown Primary Marine Wire | Generator Alternator Charge Light Pumps |

Generator Armature to Regulator Auxiliary Terminal to Light to Regulator Fuse or Switch to Gauge |

22AWG - 10AWG |

| Red Primary Marine Wire | DC Positive Conductor | Positive Mains | 22AWG - 8AWG |

| Orange Primary Marine Wire | Accessory Feed Common Feed |

Ammeter to Alternator or Generator Output Distribution Panel to Accessory Switch |

22AWG - 10AWG |

| Yellow Primary Marine Wire | Bilge Blowers DC Output |

Fuse or Switch to Blower Negative Mains |

22AWG - 8AWG |

| Green Primary Marine Wire | Bonding | Bonding wire to Fuel | 22AWG - 8AWG |

| Light Green Primary Marine Wire | Ballast Pumps | Fuse or Switch to Pump | 16AWG - 14AWG |

| Blue Primary Marine Wire | Cabinet Instrument General Lighting |

Fuse or Switch to Lights | 22AWG - 10AWG |

| Light Blue Primary Marine Wire | Oil Pressure | Oil Pressure Sender to Gauge | 16AWG - 14AWG |

| Violet Primary Marine Wire | Ignition Instrument Feed |

Ignition Switch to Coil & Instruments Distribution Panel to Instruments |

22AWG - 10AWG |

| Grey Primary Marine Wire | Navigation Lights Tachometer |

Fuse or Switch to Lights Tachometer Sender to Gauge |

22AWG - 10AWG |

| White Primary Marine Wire | General Alarm Usage | Fuse or Switch to Alarm | 22AWG - 8AWG |

| Tan Primary Marine Wire | Water Temperature | Water Temp. Sender to Gauge | 16AWG - 14AWG |

| Pink Primary Marine Wire | Fuel Gauge | Fuel Gauge Sender to Gauge | 16AWG - 14AWG |

What if I need more color options?

Even though we offer fourteen different colors for insulation on our wire, we know that some jobs call for more. This is why we offer stripped primary marine wire. By adding stripes, we increase the number of possible combinations to the hundreds. Seriously, you could buy 100 different striped Pacer wires and not even be close to running out of options. Why use striped wire? It makes the process of finding a wire's purpose much easier. This makes repair, maintenance, and replacement a much easier task. By utilizing striped marine wire, you simplify the process of navigating your electrical system.

How do you terminate Primary Marine Wire?

Terminating Pacer Primary Marine Wire is easier than standard wire. Our flexible proprietary insulation, while extremely tough and durable, is surprisingly easy to strip. This makes the process of installing our primary marine wire a simple task. Once you have the proper tool, all you need to do is measure the correct amount of insulation to remove based on the terminal or connector to be used. After you have removed the insulation, you will have access to the tinned copper conductors.

The next few steps may vary depending on the terminals or connectors you are using, but the basic idea is to have the upper barrel of the terminal crimped onto the tinned copper conductors and the lower grip, or barrel, of the terminal encase the insulation of the wire. This dual grip on the wire gives strength to the connection point and reduces stress, giving a longer life to the connection. This idea, coupled with the high levels of resistance that our primary marine wire carries, makes it the ideal choice for harsh environments.

![]()

![]()

How long should my marine wire be, and what gauge should I use?

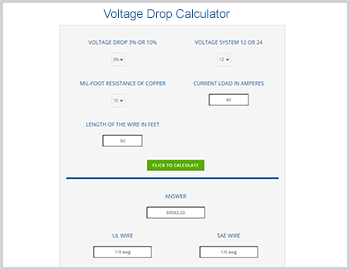

There is no one-size-fits-all answer for this question, as the length of the wire and the gauge size are determined by the power requirements of the project at hand. One factor that should be carefully considered is voltage drop.

Voltage drop is the process by which electrical potential is reduced due to the resistance or impedance of the wire itself. This dissipation of energy affects the electrical circuit. The truth is that voltage drop is an unavoidable fact of reality. The good news is that we have you covered. Pacer offers a free voltage drop calculator to make the process of selecting the right size marine wire an easy one.

What types of resistances does Pacer Primary Marine Wire offer?

Our primary marine wire is designed and manufactured to be resistant to a range of conditions such as acid, oil, alkali, moisture, abrasion, gasoline, and flame. What good is marine wire if it can’t handle exposure to marine conditions? We know that our customers and their families count on our wire to not only perform its function, but to last long term. That’s why we took every step to make our wire as resistant as possible. This way, you know if it’s Pacer wire, you have one less thing to worry about.

![]()

Moisture ![]()

Acid ![]()

Abrasion ![]()

Alkali ![]()

Oil ![]()

Gasoline ![]()

Flame

Which compliances does Pacer Wire meet or exceed?

Pacer Primary Marine Wire meets or exceeds a range of compliances. We know how important wire is in an electrical system, and we know how much trust you, your friends, and your family put in us when you use our Primary Marine Wire. That is why we make sure that our wire exceeds many of the standards such as Underwriters Laboratory (UL), American Boat and Yacht Council (ABYC), The United States Coast Guard (USCG), and the CSA (Compliance, Safety, and Accountability) measurement. Below you will find a complete list of the compliances we meet or exceed. Click on the link to be taken to an explanation of the proper compliance.

16 AWG - 8 AWG

22 AWG - 18 AWG

What makes Pacer Marine Wire superior to the competition?

Pacer's Primary Marine Wire is superior to the competition in several ways, including enhanced flexibility, resistance to environmental hazards, and exceeding compliances, but there’s even more than that. When choosing the right wire for your boat, you want one that is going to give you the most advantageous results. Pacer Primary Marine Wire carries proprietary insulation that was designed in-house by our long-term engineers. These are people with multiple decades of experience. We use a proprietary formula that contains only virgin PVC. Never regrind of any kind.

It’s easy to say that your product is the best on the market. Nearly every manufacturer will boast that kind of marketing tactic at some point, but how do they prove it? We prove it every day, with every one of our customers that comes back to us time and time again. We prove it with our wire that exceeds the standards set in place by the industry when other companies fail to even meet those standards. We prove it when we take time to constantly refine our products. You can find Pacer Primary Marine Wire and thousands of other products in our Hollywood, FL, retail and distribution center. Learn more about our brick-and-mortar store here.

Which industries use Pacer wire?

Pacer Primary Marine Wire can be found in such industries as marine, automotive, alternative energy, power management, and more. Take a look at the list below to see some of the larger industries where you will find our primary wire being used on a daily basis.

![]()

Marine

![]()

Automotive

![]()

RV's

![]()

Communication

![]()

Golf Cart

![]()

Audio

![]()

Solar

![]()

Batteries

![]()

Database

![]()

Equipment

*This page was updated on 1/30/2025*