Categories

- Wire & Cable

- Multi-conductor & Signal Cable

- Battery Cable Assemblies

- Terminals and Connectors

- Electrical Parts

- Electrical Tools

- ID Products

- Wire Management

- Tape & Sealant

- Mounting Panels & Panel Blanks

Need Help?

Click HereGet a Business Account

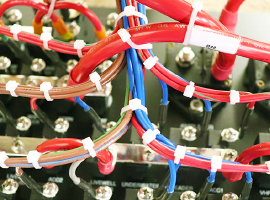

Apply HereWire Management

What is wire management?

Wire management, also known as cable management, is the use of specialized tools and equipment to control the direction or organization of wires or to protect the functionality of wires in an electrical system. This is done for a variety of reasons including; protecting wires from environmental hazards, simplifying the process of navigating the electrical system, and segregating wires by function or intended location using a cable organizer. The term wire management can refer to a wide range of items and tools such as that are used in the process of managing wiring systems. Anything from cable ties and cable clamps to heat shrink and expandable sleeving fall under this category. Basically, if it helps protect or navigate wires, it can be considered wire management or cable management. The overall benefit of utilizing wire management tools and techniques such as cable management sleeve is that you can extend the life of your electrical system by protecting the wires themselves while making it easier to find the wires you’re looking for.

"you can extend the life of your electrical system by protecting the wires themselves while making it easier to find the wires you’re looking for."

Where are these products implemented?

Wire management materials can increase the longevity of your equipment

Wire management materials are implemented in applications where wire and cable bundles need to be protected from environmental hazards. These tools are used in long-term applications where high level protection is a must. They can be used on new installations as well as when replacing parts. Suppose you have damaged wire management materials such as broken cable ties, then these wire management materials are perfect for you. All you will need are the proper marine wire and battery cable. Now let us look at how many cable tie styles are available.

How many cable ties styles are available?

We offer nylon cable ties, nylon cable ties with mounting rings, dome-top barb cable ties both with and without mounting rings, and stainless-steel cable ties. Cable ties are a common choice of cable organizer by many professionals due to their versatility. They can be used in so many different ways that it would take days to list them all. Seriously, you can use them to bundle items, run wires along walls or other surfaces, attach cracked plastic, for cable management and so much more. Cable ties usually come in two main varieties; natural and black. Natural is your everyday common use cable tie and is built for everyday use. Black, on the other hand, is UV resistant and built to be the tougher, longer lasting option. All pacer cable ties are available in either white or black other than stainless steel.

Nylon Cable Ties

These are your everyday cable ties that people think of when you use the term. They are made from 6.6 nylon and are designed for indoor or outdoor usage. The versatility of this cable organizer is what makes them so common. When selecting the correct type of nylon cable tie for your project, one major consideration is the tensile strength. Tensile strength is a measurement of the resistance required for the cable tie to break under tension. This way, you can choose the nylon cable tie strong enough to handle even industrial tasks.

Nylon cable ties with mounting rings

This type of cable management offers the same benefits as regular nylon cable ties with the added bonus of a mounting ring. The mounting ring allows you to install the cable ties on just about any surface that can hold the tension. This means you can run wires along a wall, ceiling, underside of a table, and a host of other locations. All you need is a #4 - #10 size screw and you can easily begin mounting. Just as mentioned above, the first consideration with this type of wire management should be how much weight it will need to hold, and then base your selection on the tensile strength.

Dome-top barb ty cable ties

This type of cable tie is a step up from the common nylon cable tie. They are the ideal high-end wire bundling solution for professional and industrial usage. Rather than a nylon locking tongue, dome top barb ty cable ties carry a stainless-steel tongue and provide superior reliability, performance, and adjustability when compared to other types. The high tensile strength of dome top cable ties exceeds industry and military standards.

Dome-top barb ty cable ties with mounting rings

When you need to mount a run of wires or secure something to a table, these are the cable ties you’ll want to use. They offer the same advantages of the dome top barb ty cable ties with the addition of the mounting ring. This way you can have the level of strength you need with the ability to mount to a multitude of surfaces. They offer high strength with low tread force making them the optimal solution for many wire management and cable management situations.

Stainless-steel cable ties

Sometimes a job needs to withstand the test of time. When you need to bundle wires or cables for an extended period of time, stainless-steel cable ties are the best solution. Being made from metal means they will outlive any of the nylon options by years. If you need to secure something but are worried about the metal edge of the cable tie damaging the surface, you can add cushion sleeves to insulate and protect for long term durability. This is the toughest and most versatile form of cable management you'll find.

What are cable tie mounts?

Cable ties mounts are a cable management option used in situations where you either can’t use screws to mount to a surface or where the mounting position may change over time. In these situations, cable tie mounts offer an easy way to make adjustments without damaging a wall or other surface. There are three main styles of cable tie mounts, each with their own specific advantages and uses. Knowing which style is right for your project will make installation and interaction an easier process.

Adhesive backed mounts - In some cases, you will want to mount a run of wires to a wall, ceiling, or other surfaces that you can’t or don’t want to screw into. In these situations, adhesive backed mounts allow you to mount to the desired surface without causing any damage. For long term reliability, a superior adhesive is used to make sure that the mount will not come loose or fall. Additionally, adhesive backed mounts offer four-way cable tie entry meaning that you can use them from multiple directions. This form of wire management is useful due to its versatility.

Screw down mounts - These cradles are designed so that they can be quickly and easily installed with little damage to the mounting surface. They carry a strong adhesive in order to support the necessary weight to handle industrial jobs. Additionally, they are low profile and offer excellent rigidity and stability. This way, when you need to adjust the wire run placement, you won’t need to remove the screw, but rather just replace the tie. Their small size makes them ideal for situations where appearance is a concern making them an ideal cable organizer for wire management usage.

Multiple tie mounting plates - Certain situations will require that several wire runs are in close proximity to each other. In these cases, multiple tie mounting plates are the perfect wire management or cable management solution. They offer you the ability to mount parallel runs while reducing the number of fasteners involved. They are a great choice as a cable organizer as they uniformly anchor parallel wire runs, bundles, cables, tubing, and more in one convenient location. You can easily mount 3 or even 6 wire runs parallel to each other by utilizing multiple tie mounting plates.

Where would I use cable clamps?

Cable tie mounts are useful for smaller wire runs but some situations will call for larger wire and cable runs. Once the diameter reaches a certain point, you need to consider cable clamps. These are the next step up from cable ties and their mounts as they are designed to handle much more weight. Cable clamps come in two main varieties, nylon and stainless steel. These are the ideal choice when weight and vibration are considerations. Additionally, they are resistant to acids, oils, flame, and even grease making them a solid choice for cable management. So how do you know which one is right for your project? The easiest way to determine the cable clamp you need is to determine the level of longevity you expect. Below we will take a look at both types of cable clamps.

![]() Nylon cable clamps

Nylon cable clamps

This style of cable clamp is available in both natural and black with black offering additional resistances. These resistances include; UV resistance and heat stabilization. You may see these referred to as BCCH (Battery Clamp Cable Hulls). They are a fast, durable cable management solution when you need to mount hoses, tubes, cables, or more in an efficient manner. The width is always at ½” for superior strength, so your only concern is the diameter you will need to bundle.

Stainless steel clamps

Stainless steel clamps

These are the ultimate cable clamp when it comes to durability and longevity. Made from 321 stainless steel, they are able to handle weight limits that the nylon cable clamps cannot achieve. Each stainless-steel cable clamp carries a black neoprene cushion for an extra level of protection. The neoprene cushions dampen vibrations and protect the surface from contact with the metal. These cable clamps are easy to install and built to last for an extended period of time.

How useful are cable pass-throughs?

Cable pass-throughs are extremely useful as a cable management solution as they offer the ability to create watertight pathways through thin walls or other obstructions. No other product family offers an ability like that. Think about it, sometimes you’ll need to run a cable through a wall, but you may need the connection to be watertight. This is where cable pass-throughs are an ideal solution. They are available in three options, cable glands, cable clams, and snap bushings. Of the three only snap bushings do not create a watertight seal, but they are still very useful as you’ll see further down.

"sometimes you’ll need to run a cable through a wall, but you may need the connection to be watertight. This is where cable pass-throughs are an ideal solution."

What is the difference between NPT and PG Glands?

When dealing with NPT and PG glands, the biggest difference is size where NPT ranges in diameter from roughly 3/8” to 1” and PG ranges in diameter from roughly 1 ¼” to 1 ½”. So, you really need to consider the diameter of your cable when choosing either NPT or PG. NPT stands for National Pipe Thread and is a U.S. standard for measuring tapered threads on fittings as well as tapered pipes. PG stands for Panzergewinde (armored thread) and is a similar standard to NPT that is used in Germany and other places around the world. Other than the diameter, they are basically the same thing that carries the same resistances, compliances, and characteristics.

What are snap bushings?

Snap bushings are used in situations where a cable needs to pass through a wall and be protected, but a watertight seal is not needed. They serve to eliminate sharp edges in the opening of a wall or similar surface and create a safe passage for cables, hoses, or anything else that needs to be passed through. They are built to handle a range of box or panel thicknesses and easily snap into place, hence the name. The most important consideration when choosing a snap bushing is the thickness of the panel or surface you will be using. Use the table below to help determine the size of the snap bushing that is right for your project.

| Panel Thickness | Diameter of Bushing |

|---|---|

| Up to 0.062" (1.6mm) | 1/4" |

| Up to 0.125" (3.2mm) | 3/8", 1/2", 5/8", 3/4", 7/8", 1", 1 1/8", 1 3/8", 1 1/2", 1 3/4", 2" |

| Up to 0.250" (6.4mm) | 2 1/2" |

What are Cable clams?

Cable clams are a watertight way to pass cables through a solid surface such as a wall. They are useful for passing an antenna or transducer cable through a solid surface without having to remove the cable connector installed by the factory. In this way, you create a watertight seal for your cables. The major benefit is that you save the expense of removing and replacing factory connectors and avoid poor connections you get from replacing those connectors. They have a body made from acetate and a seal made from UV stabilized Buna-N rubber. This makes them a perfectly suited cable management solution for use in a marine environment.

Which types of heat shrink are available?

We currently offer 3-to-1 heat shrink and heavy wall heat shrink online but carry many more varieties at our distribution facility. Both 3-to-1 heat shrink and heavy wall heat shrink are multi-purpose products designed to; protect, insulate, and seal electrical connections and wire terminations. As the name implies, it is designed to shrink as heat is applied to it. Heat shrink, in general, can be used for a wide variety of tasks. The thing about heat shrink is that each type has a specified use where it is designed to excel.

3-to-1 heat shrink - This is a flexible polyolefin tube that has an inner lining of adhesive. That adhesive activates and flows when heated creating a complete seal as the heat shrink decreases in diameter. As the name indicates, the shrink ratio is 3:1 meaning the diameter is one third its original size after heating. 3-to-1 heat shrink offers strain relief, moisture-proof sealing, and even abrasion and vibration protection. The best part is that 3-to-1 heat shrink is easy to install and simple to use.

Heavy Wall Heat Shrink - One major issue with many types of heat shrink is that they do not offer a high level of protection. An alternative that corrects this is heavy wall heat shrink. Just like the name implies, this heat shrink is built with a thicker, heavy wall. This style of heat shrink offers the mechanical strength of a superior adhesive and the corrosion protection of a high-quality mastic. This can increase the durability of the splice and reduce the strain on the connection.

What is wire routing? How is it useful?

Wire routing is a term used to describe cable management sleeve products whose direct purpose is to route a run of wires. More than just routing, each of these products also offers some level of protection against abrasion as well as other environmental hazards. Each of these cable management sleeve products is built with ease of use in mind in order to make installation a simple task. Some are wrapped around the wire run while others are slid over the wires. The most important thing to consider is the level of protection your wire run will need. Once you know that, the only other concerns are how flexible you need the wire routing material to be and what diameter your wire run will be. Once you have this information, selecting the correct cable management sleeve becomes a simpler task.

![]() Slit Conduit

Slit Conduit

A superior general-purpose harness and cable protector, slit conduit is a solid choice for protection and ease of installation. Using slit conduit will increase a wire runs resistance to impact and abrasion. It has a slit down the center which you open to place your wires in. It is this design that makes installation a much simpler task. To make this cable management sleeve even more appealing, it offers a high level of flexibility meaning it can meet the twists and turns found in a boat hull or similarly tight location.

![]() Spiral Wrap

Spiral Wrap

Some types of cable management sleeves are designed to be used with more than just wire. Spiral wrap is an ideal choice if you’re looking to protect hydraulic or pneumatic tubing from abrasion. Additionally, when used with tubing, spiral wrap helps to prevent kinks from blocking the flow. If you need more protection, make the wrap butt up to itself. If your project calls for more flexibility, add gaps instead of butting up. This way, you have a variety of choices in how you apply spiral wrap and the outcome you’ll receive.

![]() Expandable Sleeving

Expandable Sleeving

This type of cable management sleeve is often used in high-tech and electronic applications as it is flame retardant and extremely durable. The fact that it is easy to install is another reason many professionals prefer this type of cable management sleeve. To use, you simply open it up and slide it over the wire run you need to protect. Once you are done, pull both ends which will stretch it and create a tighter fit. Easy to install and highly durable makes a product more than useful. It makes it essential.

Expandable Sleeving

Expandable Sleeving

This type of cable management sleeve is often used in high-tech and electronic applications as it is flame retardant and extremely durable. The fact that it is easy to install is another reason many professionals prefer this type of cable management sleeve. To use, you simply open it up and slide it over the wire run you need to protect. Once you are done, pull both ends which will stretch it and create a tighter fit. Easy to install and highly durable makes a product more than useful. It makes it essential.

Why choose Pacer?

We have always strived to grow and expand our knowledge base which, in turn, allows us to offer more and greater solutions. With forty years experience in the marine industry, we have mastered our craft. We may have started with manufacturing wire and cable but, as I said, we strive to grow leading us to gain knowledge and expertise in a wide range of fields. We use this expertise to offer electrical solutions to all our customers. We have cultivated a product catalog that only handles the highest levels of quality. We trust these products so much, we use them in our own personal boats. In this way, you know that when you see Pacer, you know it’s a name that you can trust.

*This page was updated on 2/08/2023*