Categories

- Wire & Cable

- Multi-conductor & Signal Cable

- Battery Cable Assemblies

- Terminals and Connectors

- Electrical Parts

- Electrical Tools

- ID Products

- Wire Management

- Tape & Sealant

- Mounting Panels & Panel Blanks

Need Help?

Click HereGet a Business Account

Apply HereRing Terminals

What are ring terminals?

Ring terminals are electrical connectors designed to secure wires to a connection point by fitting the terminal over a stud. They create a strong, reliable connection that cannot come loose or fall off, making them ideal for long-term use. Known for their durability, these crimp connectors provide a semi-permanent connection and can accommodate multiple wires depending on the application. As the most secure type of crimp connector, ring terminals are favored for their reliability in tough conditions.

"They create a strong, reliable connection that cannot come loose or fall off, making them ideal for long-term use."

How do you use ring terminals?

Installing ring terminals is easier than you may think. The first thing you need is the proper tool. Depending on the types of crimp connectors you are using, you will need specific tools. We'll be using the VTTR50 as it can crimp 22 to 8 gauge terminals. Once your wires are properly stripped and prepared simply slide the wire into the terminal body making sure the insulation butts up to the barrel of the ring terminal. Make sure you insert the terminal into the proper crimp nest. Identification is made easy by the colored dots which should match the insulation on the ring terminal. Now, simply close the tool with the terminal barrel centered. One completed cycle of the tool is all it takes to complete the crimp. When inspecting the crimp, look for clean indentations and ensure that the terminal is not damaged or bent. The next step is to activate the heat shrink using the proper tool. All that's left is the tug test. With a gentle pull, you'll be able to tell if the crimp will hold or not.

Where are ring terminals implemented?

Ring terminals are implemented in many systems

Ring terminals are implemented by boat builders, repair shops, and everyday boaters on a daily basis. They are some of the most popular terminals in use today. People use our ring terminals to not only install or repair connections, but they use them in replacement parts as well. They are known for their ease of installation and durability. When used with the proper tools, our ring terminals can be used to create high quality electrical connections. Now that we have covered the basics, let us look at how they are advantageous.

Advantages of ring terminals?

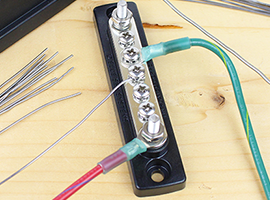

Ring terminals are advantageous as they create a semi-permanent connection point that can be accessed and adjusted if needed. They are often used in applications where the connection point, materials used, or equipment connected may be subject to change. Their versatility allows them to perform in a way other terminals cannot handle. You will commonly find them used on bus bars and other pieces of equipment where studs are present. Ring terminals offer benefits that you cannot get with other types of terminals such as fork terminals.

How do I know which stud size is the right one for my project?

Stud size refers to the diameter of the stud where the ring terminal will be attached. Available sizes include #6, #8, #10, 1/4”, 5/16”, 3/8”, and 1/2”. To determine the right size, measure the stud’s shank with a caliper or ruler. For example, if the stud measures 3/8”, you need a 3/8” ring terminal.

Ensuring the proper sizing guantees a solid fit and a stronger connection. Only use the properly sized ring terminals based on the stod diameter.

What is the difference between ring terminals and fork terminals?

Ring terminals and fork terminals carry several distinct differences and are best suited for applications where those differences offer an advantage. Ring terminals carry an open face that fits over a stud or screw and creates a lasting connection point that will not come loose or pull free. Fork terminals are fully open on one side and allow the operator to add them to a stud or screw without having to fully remove any equipment or connectors. Ring terminals offer a stronger connection point whereas fork terminals may be easier to install in certain situations.

![]()

Ring Terminal

![]()

Fork Terminal

Tools for ring terminals

Ring terminals can only be used with the correct type of crimper in order to get the strongest connection possible. Using the incorrect tool will lead to unsatisfactory results and likely compromise your electrical connections. Crimp connectors are the most secure of electrical connectors to use. The most versatile crimper we offer is the VTTR50 which can crimp any ring terminals available other than non-insulated or bare terminals. If you need to crimp non-insulated or bare terminals, use our VT3120CT which can work with all of the ring terminals available. Regardless of the electrical wire connectors you are using, these tools are built with longevity and repeatability in mind. These are the same tools that we actually use on our own internal production lines. This shows just how trustworthy these tools actually are. Think about it, would we use tools that we didn't test and trust? Not likely.

What types of ring terminals are available?

Pacer offers ring terminals in a range of gauge sizes including 22-18 AWG, 16-14 AWG, 12-10 AWG, and 8 AWG. Additionally, we offer them in heat shrink, nylon, vinyl, and non-insulated. We offer so many gauge sizes and insulation types so that you can find exactly what you need to finish your project. By offering you the most options possible, we give you the ability to find the ideal solution.

22AWG-18AWG

16AWG-14AWG

12AWG-10AWG

Does the insulation type really matter?

The insulation on a ring terminal plays a major role in the quality and longevity of the connection. Heat shrink ring terminals offer the longest-lasting protection and create an environmental seal. They accomplish this with the epoxy that lines the interior of the terminal. As you activate the heat shrink, that epoxy melts and creates a durable, moisture-proof seal. Nylon insulation ring terminals are the next step down. They offer the same durable connection, just without the epoxy-lined seal. Vinyl insulation is more rigid and offers slightly less protection but is more cost-effective. The non-insulated, or bare terminals are the most affordable option but that comes at the cost of added protections. So, you can see just how important selecting the right insulation for needs can be.

Heat Shrink

Nylon

Vinyl

Non-Insulated

Does Pacer offer ring terminals that create environmentally sealed connections?

Yes, Pacer does offer ring terminals that can be used to create environmentally sealed connections. It is important to note that not all Pacer ring terminals create this type of connection. In order to get the highest quality seal possible, you have to select the correct type of ring terminal. Our epoxy lined heat shrink ring terminals offers the highest level of protection possible and create an environmental seal. They achieve this through the epoxy lining. As the heat shrink is activated, the epoxy melts and is pushed out. As it cools it creates a barrier that protects your connections from exposure.

What industries use Pacer ring terminals?

Pacer ring terminals are used by a wide range of industries that includes automotive, marine, transportation, industrial equipment, power management, data transmission, and more. Basically, you will find Pacer’s ring terminals in just about every industry that deals with electrical connections. They are known for their ease of installation and long-term durability which explains why they are such a prevalent connector. They are so popular in fact, that you will find them on job sites, in marinas, in repairs shops, and even in private garages.

Why choose Pacer?

With over 40 years of experience in the marine and wire industries, Pacer has built a reputation for quality and reliability. Supplying top boat manufacturers, repair shops, marinas, and private boaters, Pacer is a trusted industry leader. When you choose Pacer, you're choosing proven quality.

*This page was updated on 6/10/2025*