How to Get the Highest Quality Battery Cable Assemblies

Posted by Pacer on 4th Oct 2021

What you need to know to get the best results

Every boat needs to not only have high-quality battery cables but oftentimes, custom battery cable assemblies. How does one go about getting the battery cable assemblies they need? It’s easy. Either build them yourself or have an expert build them for you. Our Experts have the experience needed to make the battery cable assemblies the exact way they need to be regardless if they're for a boat, car, truck, or whatever else you need them for. Having an expert build your battery cable assemblies is the obvious way to go. Let take a look at what it takes to build your own assemblies.

Building your own assemblies

Creating your own battery cable assemblies may seem like a good idea but consider just how much is actually involved in the process. For starters, you’ll need to stock a variety of cable sizes and colors. I hope you have a lot of room for all that cable. Once you have the cable, you’re going to need cable cutters, cable strippers, cable crimpers, and heat tools. Now that you have the tools you need, make sure to pick up a variety of lug styles and sizes so that you can handle the job without needing to pick up new parts. The only thing left to get is heat shrink. Make sure to use epoxy-lined as the heat-activated glue creates a superior moisture-proof seal giving your connections extra protection in tough environments.

The next step is to select the size of cable you need whether it be as small as 6 AWG, or as large as 4/0 AWG. Using your cable cutters, cut the cable to the proper length. Next, take your cable strippers and remove the right amount of insulation based on the lug you’ll be using. Once you fit your lug over the freshly stripped cable, use the proper crimping tool to get an accurate crimp. This is important as the improper tool will give an inaccurate crimp which can lead to all types of trouble. The lug should butt up to the insulation with the stripped cable pressing against the interior of the lug. Perform a test by tugging on the lug and cable to make sure the connection is very tight. If everything looks good, slide your heat shrink over the freshly made termination. Now use your heat tool to activate the heat shrink and reduce it to the proper size. Be very careful with your heat. Too little heat and the heat shrink will not activate properly. Too much heat and the cable will discolor, or the heat shrink will bubble. Either of these things will cause long-term issues. So, you see it’s a lot of products, tools, and time to create a high-quality durable battery cable assembly. We cut out all the headaches and wasted time by shipping them right to your door. Keep reading and we'll show you how we can manufacture them for you cheaper than you can do it yourself.

Find the Parts you need

If you have your heart set on doing this yourself, we sell the parts and tools you’ll need to do it correctly. Pacer carries a range of cable cutters, guaranteed to give the perfect cut. We also carry cable strippers that are designed so that they do not damage the insulation or the tinned copper conductors. Regardless of the cable crimper you need, we have them, so you can get the correct crimp each time. Heat tools are another tool we know well. Find the one you need easily and quickly. We also carry the battery cable, lugs, and heat shrink you’ll need to get the job done right.

The problem with making them yourself

Making your own assemblies requires:

1. Inventory of Cable

2. Specified Tools

3. Plenty of Time

After getting this far, you see all the planned effort and money involved with building a battery cable assembly. These are no easy products to build. One mistake and they go to the scrap bin to be recycled. Your battery cable assemblies must be built properly or not at all. With all the effort and time it takes to make these you could be doing something else that you enjoy more. What if I told you that you can actually purchase custom-made battery cable assemblies cheaper than if you made them yourself? I’m not kidding.

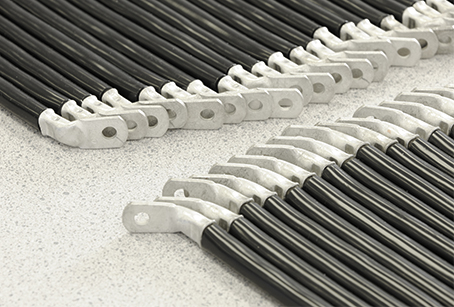

Trust the Experts that Industry Leaders turn to

Pacer has almost 40 years of experience in manufacturing wire, cable, and assemblies. We have built a reputation as a trusted name for some of the world’s largest boat builders. If multi-million-dollar companies trust us, you should too. We make battery cable assemblies every single day for some of the largest companies, machine shops, and boating enthusiasts as well. Get back to doing what you love and let the experts build your battery cable assemblies faster and at a lower price. Take a look below and see a sample of the cost difference.

Save Time and Money

Made to Order

Fast Production

Saves Money

Say you want to build three 12" battery cable assemblies made with 4/0 cable.

Remember, this comparison doesn’t factor in the tools needed, inventory stocking costs, or the time involved. If you factored those in,

the savings are much, much higher. Place an order today and see the level of quality you’ll receive when you trust the electrical solutions provider, Pacer.

*NOTE: Due to high demand, Pacer is not currently expediting battery cable assembly orders.