Benefits of Environmentally Sealed Connectors

Posted by Pacer on 7th Sep 2020

Electrical connections are only as good as the materials they are comprised of. Most electrical connections are not water-proof, weather-proof, abrasion-proof, or anything-proof. What good does that do? Like the old analogy of the chain, a system is only as strong as it's weakest link.

Why trust your electrical system to anything less than an environmentally sealed connector? Especially in marine conditions. The benefits of these connectors are easy to identify and impossible to deny. By using environmentally sealed connectors you give your electrical connections a level of protection that you cannot find with other types of connectors.

"The benefits of these connectors are easy to identify and impossible to deny."

In order to fully appreciate just how useful environmentally sealed connectors are, we need to take a look at some of the benefits that you will get from using them.

Types of Protections these Electrical Connectors Offer?

When we look at the benefits offered, the first thing you see is that your electrical connection gets protection from (insert drum roll) the environment. Now that sounds fancy and it is. This isn't some silly water-resistant or water durable title. No, this is waterproof, dust-proof, environment-proof. This is the highest level of protection from foreign objects that you can get. Aside from the high level of protection from moisture and even abrasion, these connectors also offer longevity and field serviceability. Regardless of the types of crimp connectors you use, make sure that they are properly installed to get the most benefits.

Moisture

Abrasion

Longevity

Field Service

Now that you see some of the benefits offered by using environmentally sealed connectors, let us take a deeper look at each one of these. By delving just a little further, I think you will come to realize why these connectors are so popular.

Moisture

Environmentally sealed connectors use ribbed seals that create a water-tight barrier that locks out moisture. They are so sealed that they are rated IP 6K9K. That means that they are even dust-proof, so the tiniest little pieces are still no issue for these connectors. When dealing with applications that involve water, these connectors are the best choice.

Abrasion

When the two ends of the connectors mate, they create a solid protective housing. The durable housing protects the internal conductors from impact and abrasion. This ensures that your connections are protected even in tough industrial settings. Other connectors do not offer the same level of protection that you get with environmentally sealed connectors.

Longevity

One aspect people may fail to consider is how long will an electrical connection last? If you are going to be replacing parts in a year or two, you might want to reconsider the connection method. Environmentally sealed connectors offer long term protection in harsh conditions that other types of connectors simply cannot meet.

Field Service

Often times, equipment may need to be removed periodically for maintenance or adjustment. This is where field serviceability is a must. You don't want to have to cut wires and replace connections later when you can simply plug and unplug as needed. These connectors offer the highest level of field serviceability.

What types of Connectors are available?

Environmentally sealed connectors come in a variety of sizes and styles to meet a range of needs. The biggest things to keep in mind are the wire gauge size you plan to be using and your projects' amperage requirements. Various electrical connector types offer different levels of protection. You may need specific crimp connectors or electrical wire connectors. Below we will take a more in-depth look at the various styles we carry.

DT (Deutsch Connectors)

This series is what many would consider the "standard" size. They are designed to work with 20-14 AWG wires and accept size 16 contacts. Each contact can handle 13 amps. Like many of the series, we will be looking at, the DT series offers a large number of cavity arrangements. You can readily find 2, 3, 4, 6, 8, or 12 cavities in these connectors to handle a wide range of tasks. These connectors are ideal for any situation when the environment is a factor. Many of the world's largest boat builders trust the DT series for its ability to withstand the harshest marine environments. What other connectors can stand up to the ocean and sun and still function at an optimal level? Only use environmentally sealed connectors when dealing with your boat's electrical system. This way your wire connectors will offer the most protection possible.

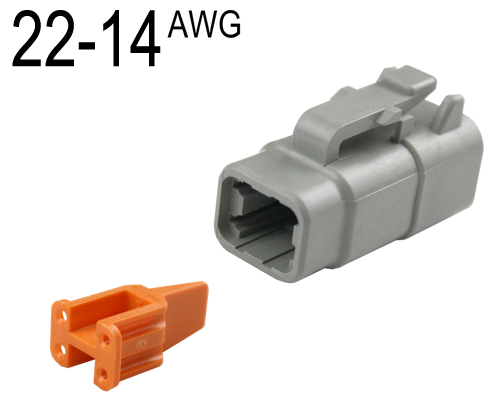

DTM (Deutsch Connectors)

The DTM series was developed to handle lower amperage needs. Each of the contacts can handle 7.5 amps. These connectors are used with 22-14 AWG wires and are designed to accept size 20 contacts. In case you were wondering, the "M" in DTM stands for "mini". Their smaller size makes them perfect for use in tight spaces. They can easily be used in locations where other connectors are just too large to fit. Like the DT Series, the DTM series is available in 2, 3, 4, 6, 8, or 12 cavities. The DTM design offers slightly more flexibility in it's design than some of the other series.

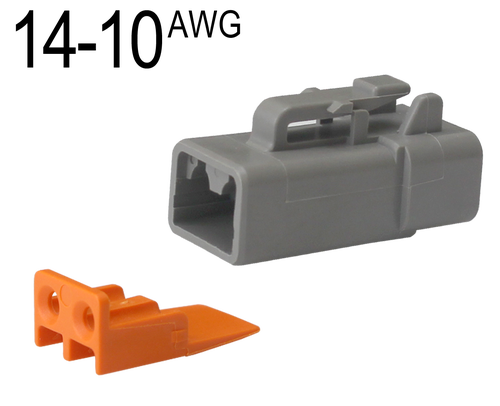

DTP (Deutsch Connectors)

Different situations call for different solutions. When your connection needs to handle higher power, that's when you would use DTP series connectors. These connectors are larger than the other series and are designed to handle a larger volume of amps. Being larger than the other series, these connectors are designed for 14-10 AWG wire and accept size 12 contacts. Each contact can handle up to 25 continuous amps. The DTP series is only available in either 2 or 4 cavities.

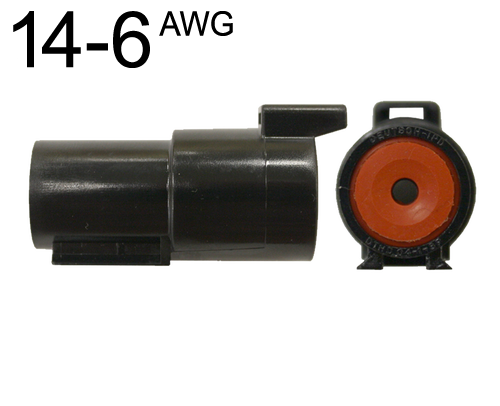

DTHD (Deutsch Connectors)

Sometimes you need to pull out the big guns and that's where you would use the DTHD series. These heavy-duty connectors are built to be used with single terminals. They are designed to handle 14-6 AWG wire and accept three different size contacts. The contact and wire size you use determine the number of amps that it will handle. You can use size 4 contacts for 100 amp protection, size 8 contacts for 60 amp protection, or size 12 contacts for 25 amp protection. Remember, these are the connectors you want protecting your electrical system in the harshest environments.

Weather Pack Kits (Delphi / Aptiv Connectors)

Delphi connectors, which are now known as Aptiv connectors are a series of environmentally sealed connectors that are well known in the automotive industry. Weather pack kits come with everything you need to create a solid connection including the tower, shroud, pin terminals, socket terminals, seals, and cavity plugs. They are a smart choice for applications where exposure to heat and moisture is an issue. Just like the types mentioned above, Delphi, or Aptiv connectors are moisture and abrasion-resistant, field serviceable, and known for longevity.

With sizes that run from 22 awg to 6 awg, you are sure to find the right size environmentally sealed connectors to handle just about any job you need. Remember to pay attention to the wire size and amperage needs of your project. These connectors are the ideal way to create an electrical connector that is built for longevity and durability. With the level of protection they offer, you are hard-pressed to find a better connector. So the next time you are creating an electrical connection, especially in a marine environment, be sure to remember the benefits of environmentally sealed connectors.