10 Essential Electrical Questions

Posted by Pacer on 6th May 2019

10 Essential Electrical Questions

*This Article was published on 5/06/2019 and was updated 11/02/2022*

When dealing with any electrical system, there is a wide range of things that need to be considered. Things that too often go overlooked, or, in some cases, are taken for granted. Your biggest concern should always be the safety of yourself and your passengers. Electrical systems can be prone to shorts, failure, or even fire, all of which can lead to disastrous results. By simply being aware of your boats inner workings as well as the condition of your electrical system, you reduce the risk of running into serious problems. Being preemptive is the best way to stay ahead of any problems before they show up.

Every boater will make mistakes. It's a fact. Hopefully, each boater will learn from their mistakes. It's how we get better at what we do, however, some of those mistakes can be deadly and as such, should be avoided. From our decades of experience on the water, we have come up with ten essential electrical questions that every boater should be asking themselves. By no means will these questions cover every possible topic, and they're not meant to. They are meant to give you a starting point and to help you think about these things for yourself. By being aware of these ten questions, we hope that they will promote you to look at other parts of your boat and come up with your own questions. The goal is to make sure you're are aware of aspects of your boat that tend to go unnoticed. In this way, we hold on to the idea that this article will help you in the long run, even if you don't immediately realize it.

![]()

1. Are you using the correct type of wire and cable?

Certain types of wire and cable are made to handle specific jobs. Some are rated for in-wall usage, while others are not. Many people incorrectly believe that all wire and cable are the same. This is not even close to correct. Using the wrong wire or cable can lead to adverse results. You may not notice it at first, but using the wrong parts will always lead to trouble. When dealing with the marine environment, you have to realize just how harsh that environment is. First off, there's moisture. Water and electrical systems don't tend to go well together but there's more than just water to be concerned about. There's salt, oil, vibration, UV exposure and a host of other potential issues. This is why you want to use wire and cable that is specifically designed for the harsh marine environment. Using bare copper? I don't think so. With such high levels of moisture, your cables will corrode faster than you may expect. Use stranded wire and cable that has been tinned. The tinning not only helps prevent corrosion, it actually increases the electrical conductivity. So why did I say stranded? Stranded wire and cable handles bending and vibration much better than solid wire and cable. In an environment that handles near-constant vibration, stranded wire is the way to go.

"Using bare copper? I don't think so. With such high levels of moisture, your cables will corrode faster than you may expect."

2. Are there any signs of damage to the insulation?

The insulation on your electrical wires does more than just keep you from getting shocked. They protect the conductors, and as such, your entire electrical system. Yes, they protect your wires from nicks, gouges, scrapes and more, but what you really want to know is that they protect them from corrosion. The oxidation process will absolutely destroy metal over time. In an environment that is primarily water, corrosion is an ever-present problem. If your insulation is cracked, that crack is an entry point for moisture, and eventually, corrosion to take hold. Inspect your wires to make sure that the insulation is not damaged in any way. If you see exposed metal, replace that wire immediately. When you replace it, make sure to use wire with high-quality insulation.

So, now you know you want high-quality insulation, but what exactly makes for high-quality insulation ? There are two main things to look for; flexibility and resistance. In a boat, your wires will bend, turn and coil their way through the tight spaces of your vessel. If your wire isn't flexible, you run the risk of a loss of connectivity. Make sure your wire is stranded, not solid, and ensure that it is highly flexible. Resistance is just what it sounds like. The insulation needs to be resistant to everything it's going to handle on a day to day basis. This includes; moisture, salt, flame, alkali, acid, UV radiation, abrasion, and gasoline.

3. Have you inspected for signs of chafing?

Any time wires or cable are against a surface, there is bound to be rubbing between the two. This will lead to chafing, which can wear away the insulation over time. Chafing is actually one of the leading causes of electrical fires on boats. Fires that can be prevented. Look for places where the wires pass through an opening or any location where there is lots of vibration. This is where the chafing will likely be the worst. You can prevent chafing in several ways. If you have had to pass wires or cable through a hole you cut, that hole likely has sharp edges. By using snap bushings, you can easily and quickly eliminate those sharp edges. Snap bushing literally takes about two seconds to install. If you need the entry point to be watertight, you can use cable clams. These are a surefire way to protect the wires and create a watertight point. If you need to protect a wire or cable over an extended length, use split conduit. Seriously, these steps can prevent a fire, and potentially save a life.

4. Are the wires properly managed and protected?

I have seen engine bays that looked like they had their wiring systems installed by toddlers; with wires running every which way and nothing being neat or organized. This makes it difficult to monitor, maintain, organize and repair your electrical system and will increase the cost at a repair shop. Having your electrical system disorganized leaves it unprotected and more prone to issues from flux, vibration, friction, abrasion, and more. Think about it, if there's an issue, it will take much longer to isolate the exact problem and even longer to implement a solution. You probably put a lot of time and money into your boat, why not protect your investment. There are a range of ways to protect your electrical system that won't break the bank. Using split conduit or spiral wrap is an easy, effective way to organize your electrical system and make it easier to navigate. Another common solution is to use a product as simple as cable ties. They can help to support your wire runs and create a more stable electrical system. These are just a few ways to protect your insulation and your conductors while getting more life from your electrical system.

5. Are the wires supported correctly?

Having wires that dangle means that stress is likely moved to the point of connection. This can weaken your connections and lead to an increased risk of reduced conductivity or electrical failure. Mounting your wires and cable along the wall is a surefire way to help protect the wires and cables themselves and take stress off of the connections. There are a few simple ways you can achieve this. Many people like to use cable clamps as they are designed to hold your wires and cables in place and will help displace some of the vibration and flux that they experience. Another useful method is to use cable ties, either with mounting rings or with screw down mounts. The advantage of the latter is that you can remove the cable tie, make an adjustment, and add a new cable tie to the same location without having to unscrew or replace anything.

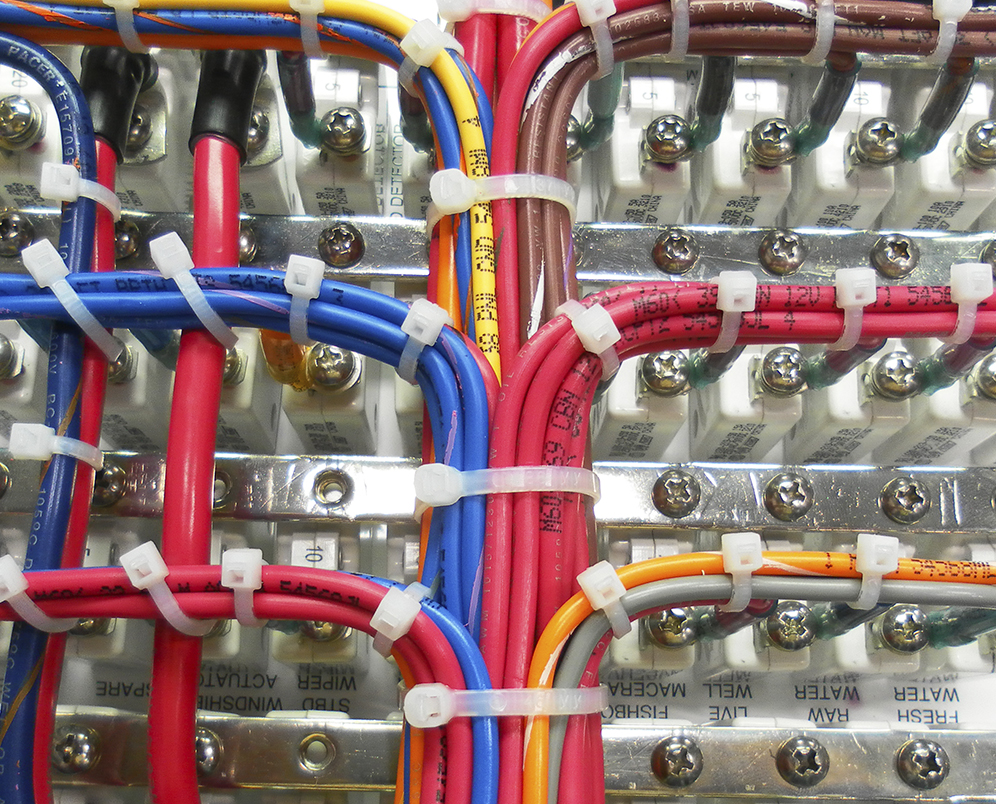

6. Are the wires labeled correctly?

Navigating an electrical system can seem like surgery with all the wires and components all interconnected and passing over and around each other. An easy way to cut down the time you spend navigating that electrical system is to use a labeling method. You can achieve this a number of ways. There are specialized write on markers, customized adhesive tape, label makers, and even premade labels from marker books. Basically, you want to label a wire or cable at both ends so that way when you need to replace the accessory lights wire, you can make sure you are disconnecting the correct wire at both ends. This task can seem daunting, I get it, but a benefit of the process is that you can check your connections, and wires at the same time meaning that you are really doing three jobs at once. Trust me, in the end, you'll be glad you labeled your electrical system, especially when you are trying to work on it.

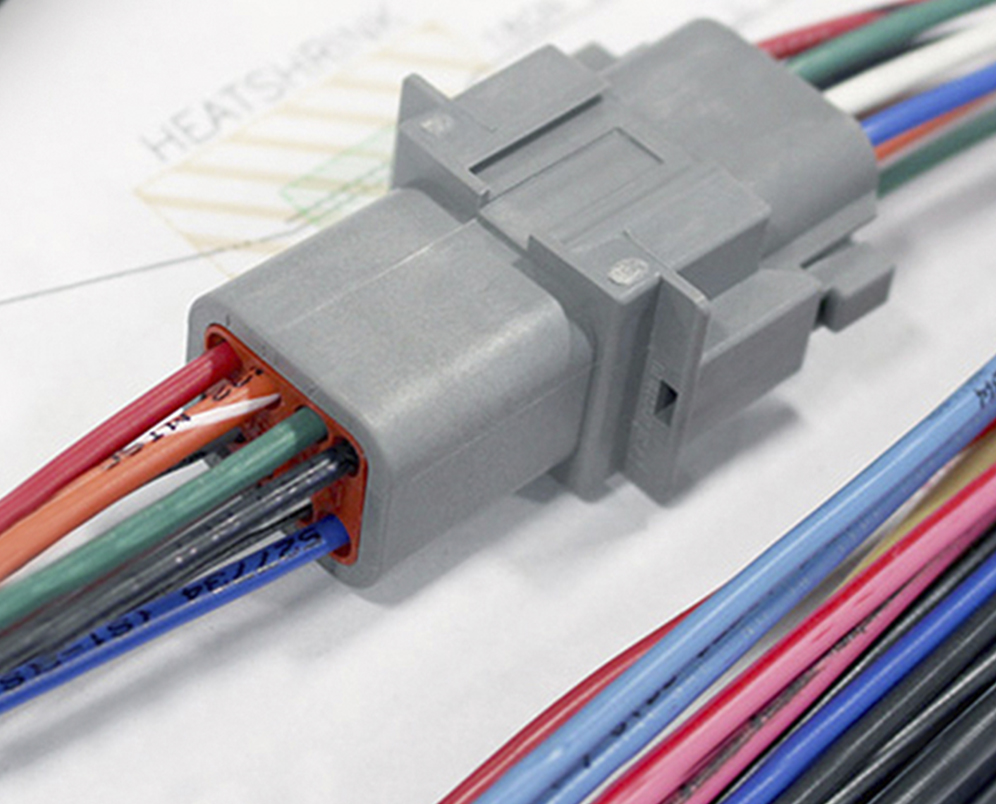

7. Have you checked how secure your connections are?

One problem with marine environments is the constant vibration. This can lead to loose connections over time. As they constantly vibrate, they tend to not hold as well as they did when they were first installed. So, should you check and tighten all your connections? Absolutely, but also consider upgrading some of them. You can use environmentally sealed connectors to create waterproof, field serviceable connection that will not come loose. Another method is to use insulated disconnects as again, they help protect against the environment and are field serviceable. Making sure that your connections are tight ensures that your electrical system will run at full power. The last thing you want to deal with is a short or loss of power due to a single screw slowly working it's way out. This preventative measure will help out tremendously in the long run. You should also use the highest quality types of crimp connectors or electrical connector types to make sure your system is protected.

8. Have your checked terminals of signs of corrosion?

Corrosion is the killer of marine electrical systems. Once it seeps in, it will spread, and before you know it, you're replacing wires, cables, connectors, and expensive equipment. Stay ahead of corrosion by inspecting your connections. Check your bus bars, terminal blocks, fuses, blocks, terminals, switches and everything else that is connected in your electrical system. If you find corrosion on crimp connectors or wire connectors, consider replacing both the connector and the wire it's attached to. One major way to combat corrosion, aside from using high-quality wire, cable, and connectors, is to use an insulating sealer. Sealers create a protective coat and can be used to help extend the life of electrical connections and certain parts.

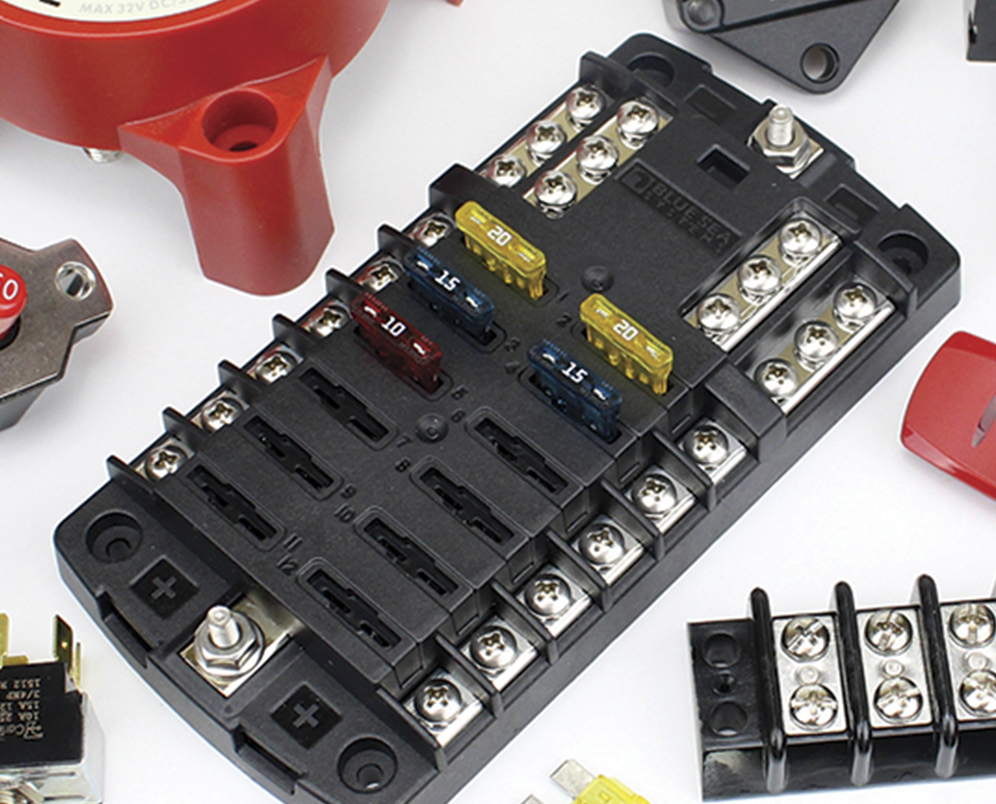

9. Are your fuses properly protected?

Simply relying on fuses is not enough. Although they serve an essential purpose, you can't just expect them to survive in a harsh marine environment. The first thing to do is make sure that you are using the correct fuses for the job, don't try to get the wrong type of fuse connected just because the amperage is correct. One smart move to make is to make sure that all your fuse blocks have covers. Those little pieces of plastic go a long way in extending the life of the block and potentially extending the life of the fuses. When fuses are protected, they are likely to last longer. Inspect your fuses and fuse blocks and if you see any signs of burning around the fuses point of entry, replace the block. It's better to be safe than sorry. The electrical wire connectors you use on your fuse also have a large impact. Make sure your electrical connectors are properly installed.

10. Is your ignition system protected?

Ignition protection helps prevent fires. In ideal situations, you want to run wires away from areas of the boat where there are exhaust fumes or other combustible gases. The problem is, this can't always be avoided. In cases where the wires need to be run through dangerous areas, make sure the components there are ignition protected. This will dramatically decrease the risk of fire and increase the overall safety of your boat. This step is so important this it is now mandatory to have certain degrees of ignition protection on your boat.

For more information about regulations regarding ignition safety, please visit this site

These are ten essential questions that will help you to enhance the safety, efficiency, and longevity of your boat. The goal is to promote you to look at things you may have overlooked or have been neglecting. This list should help you to start thinking about things related to your electrical system and your boat overall. This way, you can get one step ahead of any potential issues before they turn into problems.

"The goal is to promote you to look at things you may have overlooked or have been neglecting."