Categories

- Wire & Cable

- Multiconductor & Signal Cable

- Battery Cable Assemblies

- Terminals and Connectors

- Electrical Parts

- Electrical Tools

- ID Products

- Wire Management

- Tape & Sealant

- Mounting Panels & Panel Blanks

Need Help?

Click HereGet a Business Account

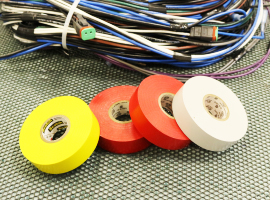

Apply HereTape & Sealant

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

What are tapes and sealants?

Tapes and sealants are used to seal and protect electrical splices, terminations, and other connections. Commonly, electrical tape is made from vinyl or rubber due to their flexibility and ability to stretch. Liquid electrical tape is made from a complex combination of chemicals to offer superior durability without compromising flexibility. These factors are important when creating a watertight seal. If you use a type of electrical tape that is not water resistant, your electrical connections will be at risk of moisture intrusion, corrosion, and other damaging conditions. Sealants are used to create a waterproof barrier around splices and connections which serve to protect that connection from a wide range of potential issues. When considering liquid electrical tape, remember, once applied it dries to a consistency that maintains flexibility. Using electrical tape and sealants is the simplest way to protect your electrical connections and ensure the longevity of your electrical system. The first step is to determine exactly what you need to protect, and which method will offer the best protection. Remember, liquid electrical tape is not right for every situation. Make sure to ask yourself the correct questions to get to the product best suited for your needs.

"Remember, liquid electrical tape is not right for every situation. Make sure to ask yourself the correct questions to get to the product best suited for your needs."

Where are tapes and sealants implemented?

Tapes and sealants offer advantages other products do not

Tapes and sealants are implemented in applications where electrical connections need a higher degree of protection. This is why Pacer's tapes and sealants are ideal for use in the harsh marine environments. They are equally useful in new installations as well as when maintaining or replacing parts. Pacer offers multiple styles of electrical tapes and many sealants so that you can find the exact parts you're looking for. Most of these products work well with marine wire or battery cable. With that covered, let us take a look at what types of tapes are available.

What types of tape are available?

Not every type of electrical tape is ideal in every situation. Tapes are made specifically to handle certain applications or conditions. Knowing which type of electrical tape is best suited for your application is the best way to ensure the protection and longevity of your electrical system. Some situations may call for liquid electrical tape whereas others will not. We carry multiple styles of electrical tape in order to offer the most solutions possible. This way, regardless of your project or application, you’ll find what you need here. Remember, carefully consider where you will be using your electrical tape and what you’ll be using it on.

3M 35

- This is what many people think of when they hear the term electrical tape. Commonly, it is used as a general-purpose insulating tape, Our 3M 35 tape is high quality, durable electrical tape, not the normal everyday kind. It is built for strength, adherence, and durability meaning it is built to last. Available in ten colors, this tape is resistant to; abrasion, UV rays, moisture, alkali, and solvents making it an extremely durable choice of electrical tape and ideal for industrial applications.

Super 33+

- Electrical tape can come in different levels of strength to handle different applications. Super 33+ is a premium grade 7-mil tape designed to be applied in temperatures as low as -18°C/0°F. To make it even better, it has an operating temperature of 105°C/220°F. It is commonly used as primary insulation for wire and cable splices up to 60 volts. It is also used for fixtures and wire splices up to 1kV. For added longevity, this electrical tape is resistant to a range of conditions such as UV rays, abrasion, moisture, solvents, and much more.

Linerless

- Although many tapes are made from vinyl, different requirements call for different materials. Linerless tape is made from rubber due to its electrical insulating ability. This electrical tape is a high voltage insulating tape that is designed to provide excellent heat dissipation for splices. Often times, it is used with splicing, terminating wires or cables, sealing moisture tight connections, insulating bus bars, and end-sealing cables. You will be hard pressed to find an electrical tape as tough and resilient as this one.

What size tapes are available?

Each style of tape we carry is designed for specific purposes and as such, may vary in length or width from the other types. Below you will find some easy to read tables that make identifying the electrical tape you need easier than ever.

| Color | Width | Length |

|---|---|---|

| Black Electrical Tape | 3/4" | 60' |

| Brown Electrical Tape | 3/4" | 66' |

| Red Electrical Tape | 3/4" | 66' |

| Orange Electrical Tape | 3/4" | 66' |

| Yellow Electrical Tape | 3/4" | 66' |

| Green Electrical Tape | 3/4" | 66' |

| Blue Electrical Tape | 3/4" | 66' |

| Purple Electrical Tape | 3/4" | 66' |

| Grey Electrical Tape | 3/4" | 66' |

| White Electrical Tape | 3/4" | 66' |

| Color | Width | Length |

|---|---|---|

| Black Electrical Tape | 3/4" | 66' |

| Color | Width | Length |

|---|---|---|

| Black Electrical Tape | 1" | 30' |

| Black Electrical Tape | 1.5" | 30' |

How do I use Dual-lock?

Dual-lock is a self-adhering, reclose-able fastening system. The fact that it can be used over and over again makes it an invaluable resource. Rather than having to continually remove and replace a fastener, Dual lock allows you to simply reattach the item. Things like Velcro are considered hook and lock fastening systems. Dual-lock is five times stronger than conventional hook and lock materials. The adhesive backing is designed to adhere to a wide range of surfaces. When you use dual-lock, it comes in a roll that can be separated into two pieces. These pieces can be cut at any length. Once you have your desired length, simply peel the backing off one of the pieces of dual-lock and apply the freshly exposed adhesive surface to the object you’re working with. Now repeat the process with the other piece of dual-lock and a surface you want your object to adhere to. Now you can easily attach and remove the two pieces of dual-lock to itself. Using dual-lock is a simple process that offers a wide range of applications. Which sealant is right for my project? Different sealants offer different properties and knowing which one is right for your application will make all the difference. The first step is to determine the conditions your electrical connection will be exposed to. This will help you to choose the right level of protection for your electrical connection. Our sealants are a safe, durable way to protect and insulate your electrical connections. In order to select the correct type of sealant for your project, you need to know the advantages of each and what applications they are designed for.

Scotchkote - When applying a sealant, you should consider one that offers easy application and quick drying. This way you don't leave your electrical connection vulnerable. Scotchkote is designed to create a tough, weather resistant coating to insulate your electrical connections. It is resistant to oil, moisture, and abnormal weathering. Scotchkote is the one you want when you’re looking for a tough seal designed for marine environments.

Insulating Sealer - In a marine environment, rust is always a concern. Our insulating sealer is designed to handle rust and a variety of other issues. You can insulate, refinish, and protect your electrical connection all in one easy step. It adds resistance to the effects of weather, moisture, acids, alkali, and oils. You will be hard pressed to find a sealer that offers the same level of protection as our insulating sealers. Easy to use, designed to last.

Corrosion X - In some situations, you need to lubricate, penetrate and protect all at once and that’s where you want Corrosion X. It uses a technology called polar bonding where the chemical literally bonds to your metal surface on a molecular level. Seriously, this stuff is so potent that NASA uses it on their spacecraft. You don’t get tougher than that. When you need protection and lubrication in one product, you’ll find it with Corrosion X.

"So potent that NASA uses it on their spacecraft. You don't get tougher than that. when you need protection and lubrication in one product, you'll find it with Corrosion X."

Why choose Pacer?

Pacer has built a reputation as an industry leader. With four decades in the marine industry, we know what works, and what doesn’t. That’s how we became the company that some of the world’s biggest boat builders turn to for their solutions. Over the years, we have seen products come and go and we learned what to look for in quality products. This is why we carry electrical tape, sealants, and even liquid electrical tape. We have hand tested each of these to ensure they offer the level of quality we expect. You can rest assured that when you see Pacer, you know it’s a product you can trust. We offer solutions, and the products you see here are the same products we use in our own personal boats.

*This page was updated on 2/08/2023*